So… how does one avoid this?

I brought this Sage Evoke 10 to a fly shop to get the 30# backing I needed to go throw in the general direction of some decent sized tarpon. The trip came and went. The tarpon were no so interested, but I did catch some cuda and jacks on the Evoke.

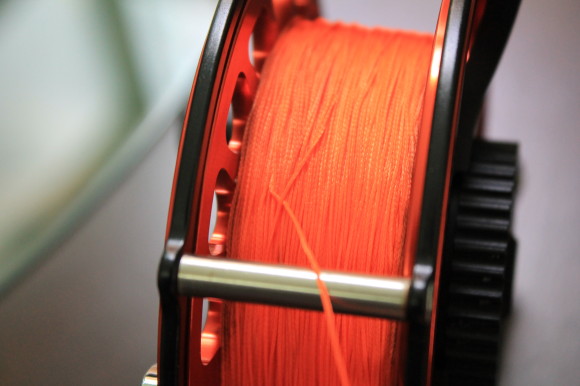

As I was stripping off the line in preparation to send it back to Sage I found the unhappy surprise of some serious cross-winding in the backing.

What does one need to do to keep this from happening? I can only imagine how bad this would have been had I managed to stick one of those 60-80 pound poons. I’d like to not bring such a potential gear malfunction with me next time.

See… that’s not good.

Tags: cross-winding, malfunction

Not a clue, I’d love to figure out how to eliminate it myself. It’s quite dangerous when I’m right in the middle of tying the best fly ever and my thread spool won’t unwind anymore because of crosswinding.

I found the start of the problem to be winding the leader onto the reel at the end of the day. The next time I used the reel, I had difficulty finding the tippet end of the leader. When I finally got the leader off the reel, I noticed it was cross threaded. That explained an event from the prior year-a tarpon running and the reel frozed-cross threaded. Know, I don’t wind the leader all the way onto the reel. I leave 8 inches or so off the reel. After putting the reel in a reel bag, I tuck the tag end in the velcro closure so I can find it without cross threading.

Every time I’ve had that happen it’s because my backing was loosely wound. Either I did it while retrieving a fish or a busted off line or the shop did it while winding on the backing. It only takes a second for a loop or two to loosely wind on the spool. It’s possible somewhere farther down the spool the line with come out from beneath the wraps. Or it’s possible when we pull off the leader to start a new day or fishing we get the leader under a loose wrap and it works its way down into the backing until it actually stops coming off the reel. In any case it’s bad.

yes, Doug is right on. Load your backing as tight and as evenly as possible and do make sure you leave your leader tip out so it doesn’t get under a wrap. It will go all the way to the core!

Bjorn,

Doug is correct about the typical reason for this. All it takes is one loop of the leader to go under itself and you’ve got yourself a problem. This is the easiest one to avoid as it’s easily detected before you go out and simply unravel. The other cause is loose line/backing. If you’ve ever done any bait casting, you’ll know that the end of birds nest can often be what seems like x-wraps. This can happen at any point, but the good news is that they come out if you go deep enough into the backing.

Every time you spool up backing or change fly lines, strip out about 5-10m of line and check for the backing to come off the spool and not from under other backing.

I spool up plenty if reels in my shop and tight backing is a must. We spool up all reels on a 10wt Xi2 someone broke ages ago. We use cotton gloves to add tension and run the line off a big spool with a line counter. I’ve never had this problem on any reel because we spool them up hard and check the tip 5-10m each time changes are made.

So how are you going to get the backing off the spool? When it happened to me I just pulled it as hard as I could. If it broke, I’d screwed and I guess it would be to break out the X-acto knife! It did come free but I was super lucky!

I like how the pros do it (Marné) using electronic winders (Maybe a good investment for BS!) The best way is to catch big bones or poons!

Best wishes.